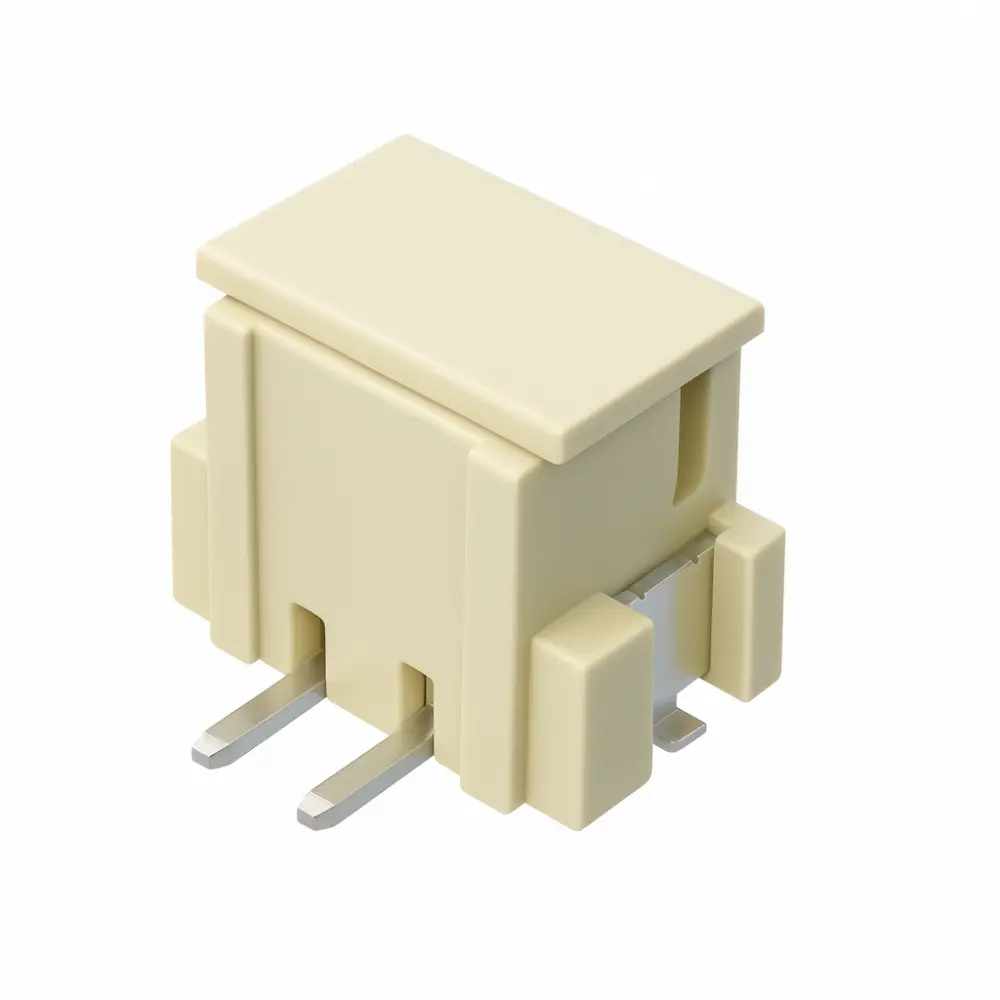

2.50mm Vertical SMT Wire-to-Board Connector from Dragon Well is a compact, single-row wafer header designed for automated assembly and dependable field performance. On tight PCBs, it delivers a low ~8 mm profile, SMT gull-wing terminals, and metal hold-down pads that resist shock and vibration. The pick-and-place cap shown in the drawing improves vacuum pickup, protects the contact tips in tape-and-reel, and keeps your reflow line smooth. This Wafer Header is designed for automated SMT with a compact profile. If you’re comparing options across our catalog of Wire-to-Board connectors, browse the family here: Wire-to-Board connectors.

Why choose the 2.50mm Vertical SMT Wire-to-Board Connector

This 2.50mm Vertical SMT Wire-to-Board Connector uses tin-plated brass terminals for consistent solderability and stable contact resistance. The insulator is LCP UL 94V-0 (see UL 94V-0), selected for heat resistance through reflow and for dimensional stability over time. The result is a header that drops into common control boards, LED bars, and compact industrial modules without drama. For an overview of our engineering and manufacturing strengths, see our capabilities page: About / Capabilities.

Drawing-derived specifications (no guesses)

- Pitch / Row: 2.50 mm, single row; positions: 2–20 (see A/B/C table).

- Mounting: Vertical (180°), SMT gull-wing terminals with metal hold-down pads.

- Key dimensions: housing height 7.90 ± 0.25 mm (max overall ≈ 8.30 mm with cap); body thickness 5.90–6.00 ± 0.25 mm; terminal spacing 0.64 ± 0.05 mm.

- Electrical ratings: 250 V AC/DC, 3 A AC/DC, ≤ 20 mΩ contact resistance, ≥ 1000 MΩ insulation resistance, dielectric withstand 1000 V AC/min, operating range −25 °C to +85 °C.

- Materials: contacts/terminals: Brass, tin plated. Insulator: LCP UL 94V-0.

- Packaging: TR = Tape & Reel.

- Compliance on drawing: RoHS COMPLIANT. (REACH SVHC and Low-Halogen available on request/certification.)

PCB layout & footprint details

The recommended layout is straightforward for pick-and-place and paste printing: pad pitch 2.50 mm, pad width 1.20 mm, with end hold-downs at 2.30 × 3.00 mm and 1.60 × 5.00 mm. These larger anchors create strong mechanical retention without over-consuming board space. Circuit count scales the overall length—see the A/B/C table (e.g., A = 2.50 mm for 2 pins up to 47.50 mm for 20 pins). Explore more single-row pin header options on our site.

Applications & fit

Use this 2.50mm Vertical SMT Wire-to-Board Connector anywhere a single-row 2.50 mm header mates with locking crimp housings: consumer appliances, LED strips and bars, compact controllers, gateways, and small industrial modules. If your design needs the mating receptacle, see our 2.50 mm crimp housing / wafer receptacle options for this header.

Assembly & reliability notes

- SMT process: The pick-and-place cap is intended for automated placement and can be removed after reflow if your process requires.

- Hold-down pads: The metal anchors are sized to increase shear resistance and improve board retention during handling.

- Inspection: The open frame around the posts makes AOI easier; verify solder fillet formation on the gull-wings and anchors.

- Mating: Pair with compatible 2.50 mm crimp housings/wafer receptacles from your BOM. Always validate insertion/withdrawal forces and latch features at the assembly stage.

Reliability, compliance & options

The series focuses on mainstream reliability: ≤ 20 mΩ contact resistance protects signals and power rails; ≥ 1000 MΩ insulation resistance keeps leakage low; and the −25 °C to +85 °C range covers typical field environments. The drawing calls out RoHS; REACH SVHC and Low-Halogen declarations are available on request. Plating and thickness options are controlled by the part-number legend—specify gold/tin selections via the code when needed.

Ordering information (used in this post)

Part number: DW-WF-125088WNP-31TR-01

This code corresponds to the configuration shown on the drawing (single row, SMT, tin-plated brass, tape-and-reel). If your project requires alternative plating or packaging, ask for the matching code from the series table. To discuss a build that matches your compliance or plating requirements, please reach out to our team Contact / RFQ.

Connect with Dragon Well

Follow us for product updates and engineering tips: