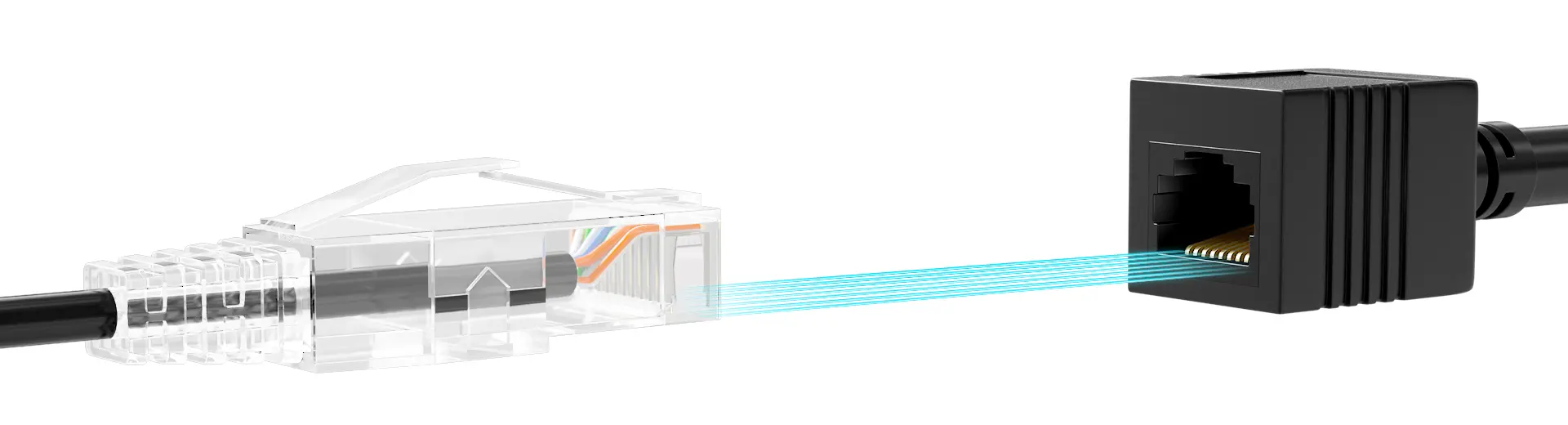

Every elegant wearable, the core of every precision self-driving car, and every seamlessly integrated smart device is the nameless hero: wire-to-board connectors. These miniature wonders bridge the gap between delicate circuitry and functional wiring, which is similar to flawless tricks – like hidden stitches in haute couture, transforming fabric into wearable art.

Accurate anatomy

Wire-to-board connectors operate according to strict engineering principles:

- Contact pitch (0.5mm – 5.0mm): Approximate stitch density made by hand-made leather, determine the connection density

- Current rating (0.5A – 30a+): Power throughput capability similar to load joints in building footwear

- Mating cycle (5–100+): Durability indicators match luxury watch mechanism

- IP rating (IP67 – IP69K): Environmental Sealed Standard Mirrored High Performance Motion Chronograph

Advanced variants have ultra-low resistance (≤10mΩ) and latch mechanism with >50n retention – Microtechnical Poetry.

Four pillars of the performance

-

Modular configuration

Customized needle meter arrangements (2-100+ positions) enable custom solutions, just like customized services made in Milan studios. Dragon Well’s proprietary Flexipin™ system allows for solderless pass-through circuit reconfiguration. -

Hybrid transmission

Next-generation connectors, such as our Synapse-X Series integration:- 10Gbps difference pair

- 5A power contact

- Fibre Channel

Inside the 3.2mm profile shell – a technology tour et al. is equivalent to embedding smart technology into luxury glasses.

-

Aesthetic Engineering

These components offer PVD-coated titanium, ceramic white and transparent smoked finishes that meet the strict visual standards of designer electronics. Our Colormatch™ program enables ΔE<1 color accuracy for seamless integration. - Zero failure criteria

Military-level testing programs include:- 500 hours salt spray (ASTM B117)

- 5,000g electric shock (MIL-STD-202)

- -55°C to 125°C thermal cycle

Ensure reliability exceeding Swiss sports certification standards.

Strategic selection criteria

-

Signal integrity factors

In high-frequency applications, skew control (<10ps) and impedance matching (±5Ω) become critical, especially in millimeter-wave radar systems in autonomous vehicles. -

Tactile Ergonomics

Balancing accessibility with child safety requirements in advanced consumer devices, fitting housings with angles of 15°-85°. - Sustainability indicators

Features of our EcoconNex series:- 97% Recycled LCP Polymer

- Halogen-free flame retardant

- Recovering gold from contact plating

Achieve completely round manufacturing.

Transformative Applications

- Wearable fashion: Ultra-low profile (0.8mm) FPC connector enables fluid circuit integration for gold jewelry tracks

- Car wall co: Board-to-wire solution withstands 40g of vibration in McLaren’s active suspension system

- Luxury airplane: EMI shielded variant ensures perfect light-dust entertainment in Gulfstream cabin

Dragon Well’s Connector Configurator Platform exemplifies our commitment to a custom solution – engineers can specify 27 parameters (from dielectric constant to click feedback) and receive prototype connectors within 72 hours.

Future reimagining

Emerging innovations include:

- Self-healing connection: Liquid metal alloy recovered from 500μm misalignment damage

- Cognitive Connectors: 500 cycle pre-shooting fee for embedded ML chip prediction failed

- Photon integration: Hybrid electrical/optical contacts can achieve 100Gbps skeleton

Just like the master cobbler reshapes the footwear craft, we are redefining the connection paradigm. A recent collaboration with the Paris Design Studio embeds our nanoconnectors into the electro-powered handbag panel – demonstrating how fundamental technologies can achieve borderless creativity.

Precise without compromise

In landscapes where 10μm misalignment could disrupt $100 million production operations, our aerospace qualification manufacturing process maintains a tolerance of ±2μm between 500m/year. The real-time AOI system performs 47 quality checks per connector, achieving six Sigma defect rates (0.00034%ppm).

From the minimalism of Bang & Olufsen’s audio ecosystem to the rugged and elegant of Breitling emergency transmitters, wire-to-board connectors represent invisible craft elevated luxury technology. They are not only components – they are conductive thread knitting innovatively into cut form.

Dragon Well Electronics: 18 years of connectivity mastery fits tomorrow’s visionary design.