Understand the basic functions of circular waterproof connectors

In this age, technology seamlessly integrates into every aspect of modern life (from luxurious smart homes to high-performance automotive systems), the need for components that combine flexibility and precision has never been more high. At the intersection of durability and functionality, is a circular waterproof connector, which is an unsung hero, which is essential for protecting the connection in demanding environments. For innovators in cutting-edge industries, from aerospace engineers to custom wearable technology designers, understanding the design, selection and application of these connectors is not negotiable.

Why waterproof connectors are not negotiable in advanced applications

Water, dust, vibration and temperature fluctuations pose a threat to electronic systems. A single compromise connection can derail mission-critical operations or reduce the user experience of luxury goods. Waterproof circular connectors solve these challenges by providing:

- Sealing seal: IP68/ip69k rating seals can prevent moisture from invasion even at extreme depths or pressures.

- Mechanical durability: The robust structure withstands shock, vibration and chemical exposure.

- Signal integrity: Gold-plated contacts and EMI shielding design ensures perfect data/power transmission.

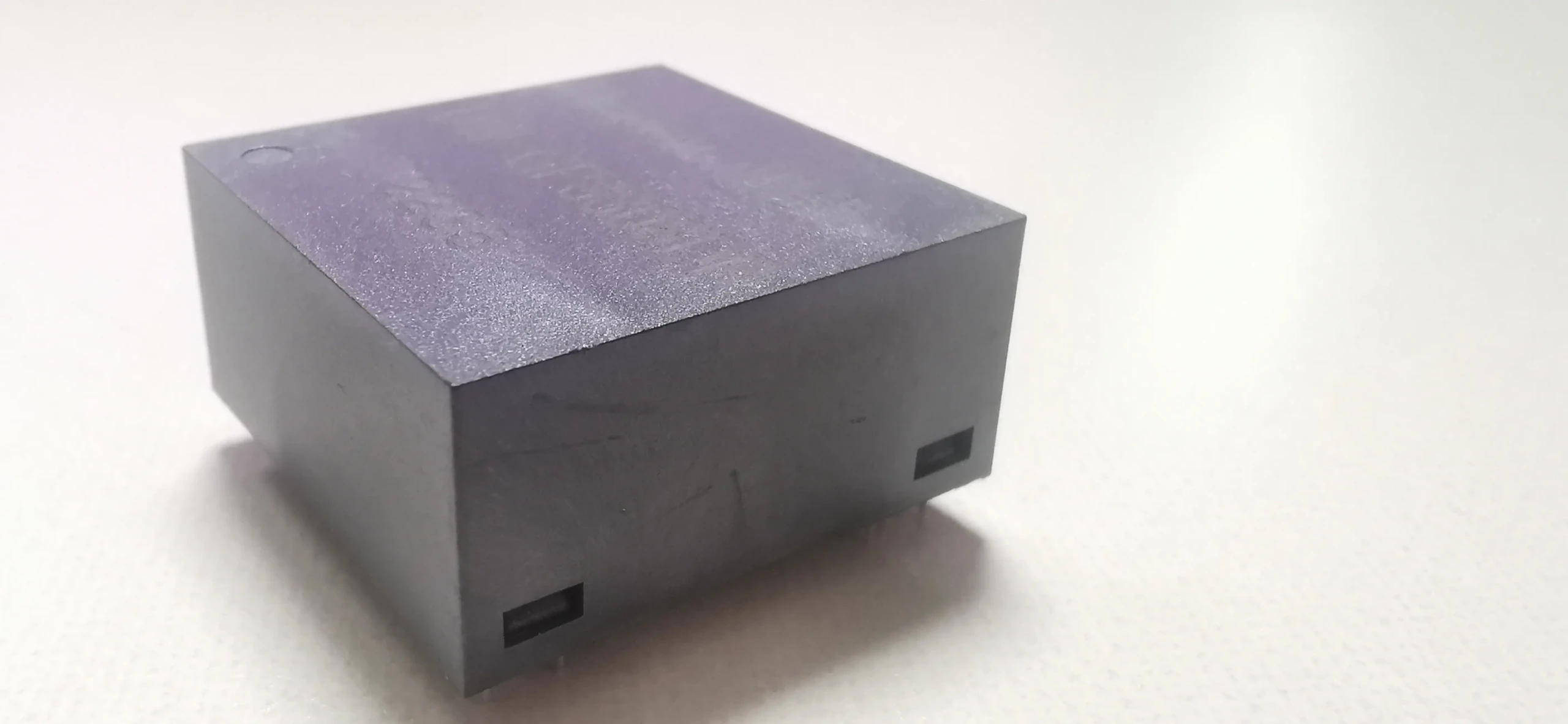

Excellent Anatomy: Deconstructed Waterproof Connector Design

Not all waterproof connectors are equal. Like Longjing Electronics, the advanced variants incorporate an innovation layer:

- Materials Science: Advanced thermoplastics (e.g., PBT, PEEK) resist corrosion and UV degradation, while silicone O-rings and TPU are too high create multi-layer seals.

- Contact Project: Accurately produced contact with gold or silver plates minimizes resistance and prevents refraction corrosion, which is crucial for low voltage applications.

- Modular: Hybrid connector combines power, data (USB, Ethernet) and fiber channel and reduces the footprint in the space-constrained design in a single footprint.

Navigation IP Rating: Beyond Marketing Hype

The Admission Protection (IP) code is your first checkpoint, but decoding it requires nuances:

- IP67: Temporary immersion (1m/30 minutes). Ideal for indoor cars or wearable technology.

- IP68: Continuous immersion (> 1m). Marine robotics or outdoor infrastructure is essential.

- IP69K: High pressure steam injection (80°C water at 80-100 bar). Used for medical sterilization or heavy machinery.

hint: For brine immersion applications (e.g., yacht systems), select a connector with other salt spray certification (e.g., IEC 60068-2-52).

Industry-specific innovation: Where performance fits gracefully

The real measure of a waterproof connector is its adaptability to the niche market:

-

Luxury Cars

Tesla and BMW utilize compact circular connectors from LIDAR and battery management systems (BMS), prioritizing Slim profiles (≤19mm) for more than 1000 mating cycles. -

High fashion wearable devices

Designers embed LED systems or biometric sensors into high-end clothing demand connectors with metal finishes (rose gold, platinum) and threadless magnetic coupling for seamless user interaction. - Aerospace and Defense

MIL-DTL-5015-compatible connectors dominate here, with a shocking shell and fail-safe locking that survives -65°C to 200°C extremes.

Four-step selection framework for identifying engineers

-

Define environmental stressors

Map temperature fluctuations, chemical exposure and mating frequency. Long-term UV exposure? Specifies UV-stabilized nylon shells. Disconnect frequently? Self-cleaning stainless steel contact is a must. -

Future voltage/data requirements

Expected today and tomorrow’s requirements. Planning to move to a 48V architecture? Select a connector rated at 1000V+. Migrating to 10GB Ethernet? Select the shielded CAT6A variant. -

Verify standard compliance

In addition to IP code, certifications such as UL (Safety), IEC 60529 (Environmental Testing) and ROHS/REACH (Material Compliance) are also ensured – especially for EU market access. - Prioritize supplier scalability

Connectors are only as good as supply chains. At Dragon Well Electronics, our real-time inventory tracking in 7 global warehouses ensures 90% of the same-day schedule – even using batches of 500,000 units to bottleneck.

Boundaries: Next Generation Connector Technology

Leading innovators are redefining possibilities:

- Nanocoated PCB: Connectors with integrated hydrophobic coatings drain moisture at the molecular level.

- Self-healing elastomer: Microcapsules rupture during seal rupture, releasing the polymer to "repair" Autonomous gap.

- Industry 4.0 Connectivity: The M12/M8 connector has real-time monitoring of contact resistance and temperature of embedded IoT sensors, thereby predicting the failure before it occurs.

Why Global Leaders Choose Longjing Electronics

For 18 years, we have been authorizing Trail Blazers (from Thales’ satellite systems to Dyson’s cordless vacuums) and blending solutions into art and engineering:

- Research and development of twisting speed: More than 400 experts have developed proprietary sealing technology (13 patents were applied for in 2023 alone).

- Beyond Connectors: We offer an end-to-end ecosystem – regular cable assembly, excess RF modules and waterproof USB-C PD 3.1 interface.

- White people love service: 24/7 technical consulting firm, rapid prototype (72 hours lead time) and forensic failure analysis.

Improve your vision with uncompromising connections

In luxury technology, the difference between impeccable and inferior quality is often located in components that end users cannot see. The circular waterproof connector, when designed to be strict standards, becomes a promoter of a seamless experience, whether it is powering the superyacht’s navigation array or ensuring that a diamond-carried smartwatch can dive at 100 meters.

At Dragon Well Electronics, we do not produce connectors. We have made the bedrock of tomorrow’s boldest ideas to connect, communicate and conquer. When failure is not an option, it is not a compromise.

[Discover how our connectors powered a Mars Rover prototype] →

[Download the 2024 Waterproof Connector Spec Guide] →