Introduction

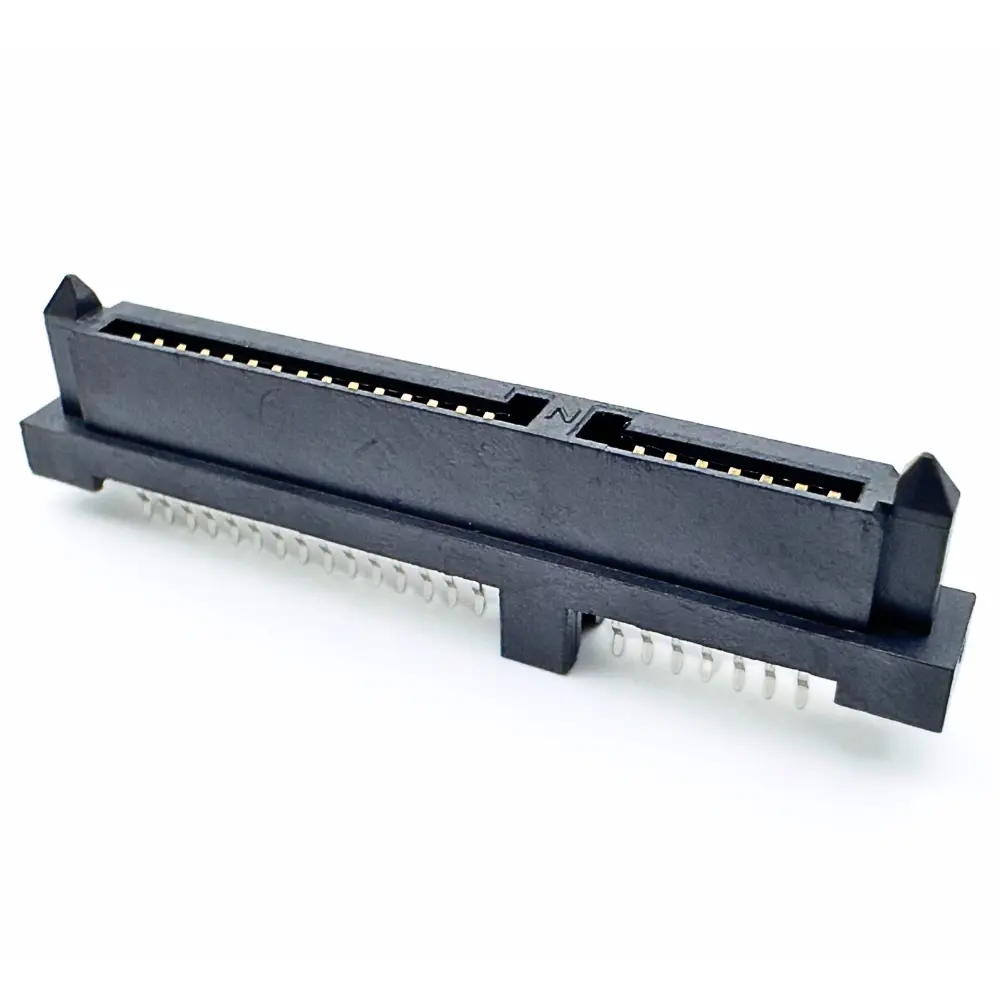

SATA 22-pin right-angle SMT receptacle designing HDD/SSD backplanes, single-board computers, DVR/NVRs, or compact storage adapters, a reliable SATA 22-pin right-angle SMT board connector is non-negotiable. Dragon Well’s DW-SAT-S22575-XXXX-01 is a right-angle, top-mount SMT receptacle that integrates the 7 signal + 15 power rows on a 1.27 mm pitch, balancing mechanical robustness with reflow-friendly solderability. With gold-plated mating contacts, matte-tin solder tails, and a proven 500-cycle durability rating, it delivers consistent performance from development to mass production.

Also called: right-angle SMT SATA connector, SATA board connector, 1.27 mm SATA connector, gold-plated SATA receptacle, SATA 7+15 connector.

Key Features at a Glance

SATA 22-pin right-angle SMT receptacle form factor

- Gold-over-nickel on mating area; matte-tin on solder tails for strong reflow joints

- Durability ≥ 500 cycles, mating force ≤ 45 N, withdrawal force ≥ 10 N

- Operating range –25 °C to +85 °C, insulation ≥ 1000 MΩ, withstand 500 VAC

- Locating pegs and reference holes for assembly accuracy; RoHS/REACH/Low-Halogen friendly

Applications

This SATA 22-pin connector is ideal for HDD/SSD backplanes, embedded IPCs, DVR/NVR, and server adapters.

HDD/SSD backplanes • SBCs and embedded IPCs • DVR/NVR • Servers & storage adapters • Industrial PCs requiring a compact SATA 22-pin right-angle SMT receptacle.

Mechanical & Layout Highlights

- Overall body length: ≈ 42.25 mm (outline on PCB: 50.00 mm)

- Recommended pad span (row-to-row): 39.50 mm (overall footprint length 43.30 mm)

- Pad width (typ.): 0.80 mm; pitch: 1.27 mm (signal & power groups)

- Standoff: 1.23 ± 0.05 mm for paste thickness control and cleaning gap

- Side depth: 9.45 mm; locating/anchor holes: Ø1.40 mm and Ø1.00 mm

- Orientation: Right-angle, top-mount SMT with segregated signal/power rows

- Durability: ≥ 500 cycles; mating ≤ 45 N, unmating ≥ 10 N

Assembly Tip: Follow the pad and keep-out dimensions from the “RECOMMENDED P.C.B LAYOUT”; respect T = ±0.05 mm tolerance to maintain coplanarity and tail wetting.

The recommended footprint keeps coplanarity tight for the SATA 22-pin right-angle SMT receptacle.

Electrical Performance

- Current rating: 1.5 A

- Contact resistance: ≤ 30 mΩ

- Insulation resistance: ≥ 1000 MΩ

- Withstand voltage: 500 VAC

Materials & Finish

- Housing: LCP, 30% GF, UL 94V-0, black

- Contacts: C2680R-H copper alloy, t = 0.25 ± 0.01 mm

- Pegs: C2680R-H, t = 0.30 ± 0.02 mm

- Finishes:

- Mating area: Gold over Ni ≥ 50 µin (plating code selectable)

- Solder tails: Matte-tin ≥ 100 µin over Ni

- Locating pegs: Tin ≥ 100 µin over Ni ≥ 50 µin

Environmental & Compliance

- Operating temperature: –25 °C to +85 °C

- Compliance: EU RoHS, REACH SVHC, Low-Halogen requirement

- Manufacturing quality: Dragon Well plants are certified ISO9001 / ISO14001 / IATF16949 with RoHS/REACH control from incoming materials to shipment.

Dimensional Summary (Design-in Quick Reference)

| Parameter | Value |

|---|---|

| Pins | 22 (7 signal + 15 power) |

| Pitch | 1.27 mm |

| Body length | ≈ 42.25 mm |

| PCB outline length | 50.00 mm |

| Footprint length (pads) | 43.30 mm |

| Pad span (row length) | 39.50 mm |

| Typical pad width | 0.80 mm |

| Standoff | 1.23 ± 0.05 mm |

| Side profile depth | 9.45 mm |

| Anchor holes | Ø1.40 mm / Ø1.00 mm |

| Mounting | Right-angle, SMT (top mount) |

Part Numbering & Options

Base P/N: DW-SAT-S22575-XXXX-01

Plating code (mating area):

- 01: Gold flash

- 03: 3 µin Au

- 06: 6 µin Au

- 15: 15 µin Au

- 30: 30 µin Au

Packing code: TR = Tape-Reel, TB = Tube, TP = Tray

Example: DW-SAT-S22575-30TP-01 → 30 µin Au on contacts, Tray packing.

Why DW-SAT-S22575 for Your Storage Board?

- Solder reliability: Nickel underplate plus matte-tin tails improve wetting and long-term joint stability in standard lead-free reflow.

- Connector life: ≥500 cycles suits service swaps and repeated lab use without unexpected resistance growth.

- Manufacturing yield: Standoff and pegs simplify paste control, placement accuracy, and AOI.

- Peace of mind: Materials and finishes align with mainstream SATA receptacle expectations, while Dragon Well’s vertically-integrated plants support NPI-to-mass with consistent quality.

Design teams standardize on this SATA 22-pin right-angle SMT receptacle for repeatable storage performance.

Recommended Reflow & Handling

- Follow your paste supplier’s Pb-free profile; keep peak below housing rating for LCP UL 94V-0.

- Use board supports under the connector during placement to prevent warp.

- After reflow, allow full cool-down before functional test to protect gold mating integrity.

Order & RFQ

Need samples or a cost-down cross-reference? Share your BOM or drawing and we’ll match plating and packing codes 1:1.

Websites: cndragonwell.com | dw-tek.com

Email: prothick@cndragonwell.com

Connect with Us

LinkedIn: Dragon Well Electronics Co., Ltd

Instagram: @dragonwell_electronics

Facebook: Dragon Well Electronics