Mastering Your Speakercraft Oe8 Speaker Wire Connector: The Ultimate Guide to Speaker Wire Connectors & Flawless Installation

Unlocking Peak Performance: Understanding the OE8 Three’s Connection System

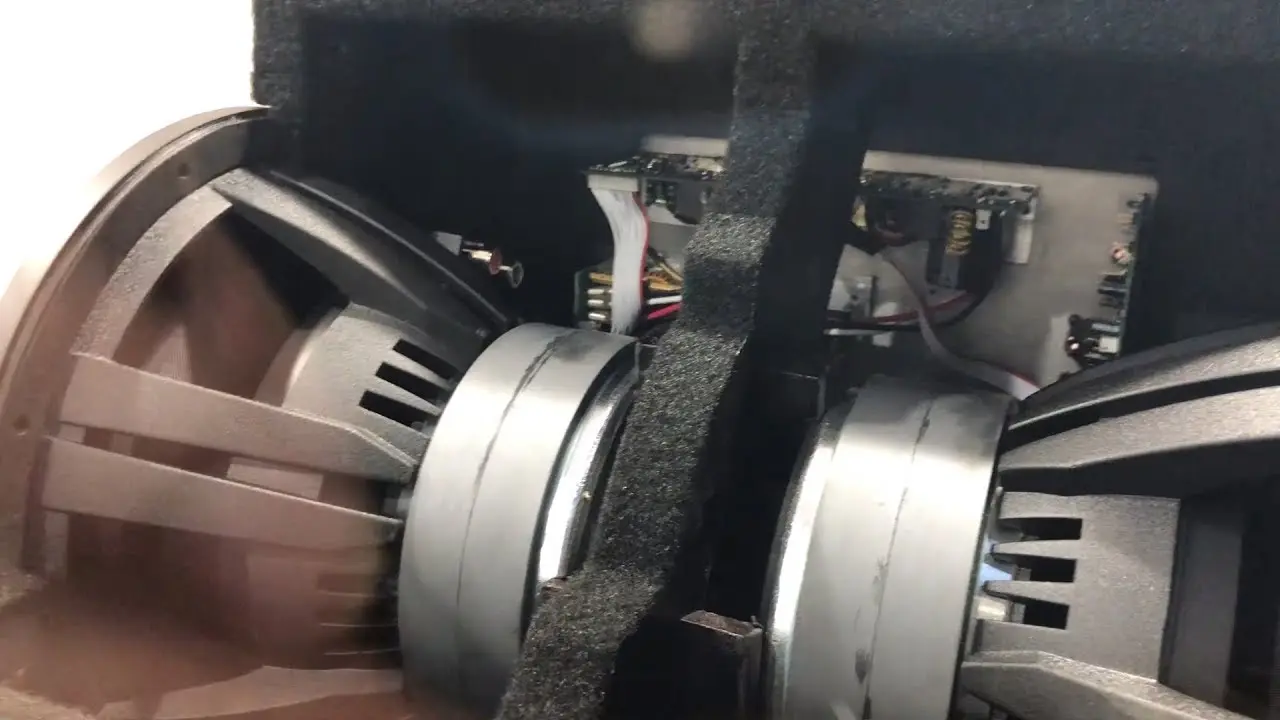

The Speakercraft OE8 Three stands as a versatile powerhouse, engineered for seamless integration into both indoor luxury audio systems and demanding outdoor environments. Its performance hinges critically on one often-overlooked element: the Speakercraft OE8 Speaker Wire Connector. This isn’t just about plugging in wires; it’s about ensuring maximum signal transfer, long-term reliability, and protection against environmental factors. This comprehensive guide dives deep into the OE8’s binding posts, explores optimal connection strategies, and provides professional-grade installation techniques to guarantee your speakers deliver their legendary sound for years.

Decoding the OE8 Three’s Binding Post Terminals

The OE8 Three features robust 5-way binding posts, offering exceptional flexibility for various connection methods. Understanding their design is key:

- Physical Construction:

- A central, knurled metal post (positive/red, negative/black).

- A threaded plastic collar surrounding the base of the post.

- A knurled plastic nut that screws down onto the collar.

- A small hole in the end of the central post (for banana plugs).

- Often, a removable plastic cap or plug covering the end hole.

- The “5-Way” Versatility Explained: This term signifies five distinct connection methods:

- Bare Wire Insertion: Inserting stripped wire directly into the port under the loosened nut/collar.

- Bare Wire Wrapping: Wrapping stripped wire clockwise around the exposed metal post before tightening the nut.

- Banana Plug: Inserting a plug directly into the hole in the end of the post (after cap removal).

- Pin Connector: Similar insertion to banana plug into the end hole.

- Spade Connector: Sliding the fork of the spade under the loosened nut and onto the metal post, then tightening.

- Robustness for Environments: These binding posts are designed for secure connections resistant to vibration and corrosion, crucial for both in-ceiling mounts and outdoor speaker installations.

Choosing the Right Path: Bare Wire vs. Connectors

Selecting the optimal OE8 Three speaker connection method depends on installation permanence, environment, and desired convenience:

- Bare Wire Connection (Direct & Cost-Effective):

- Pros: Lowest cost, simplest method requiring no additional hardware.

- Cons: Prone to stray strands causing shorts; less secure over time (vibration can loosen); susceptible to corrosion at contact points; more fiddly for final connections/disconnections.

- Best For: Permanent in-wall/in-ceiling installations where connections won’t be disturbed, budget-sensitive projects.

- Speaker Wire Connectors (Secure, Durable, Convenient):

- Pros: Eliminate stray strands; provide gas-tight, corrosion-resistant connection (especially gold-plated); highly secure against vibration; easy plug-and-play for future access/testing; professional appearance.

- Cons: Additional cost per connector.

- Best For: Any installation where reliability is paramount, outdoor speaker systems exposed to elements, systems requiring frequent reconfiguration, achieving a clean, professional finish.

Demystifying Speakercraft OE8 Speaker Wire Connectors: Types & Applications

Three primary connector types excel with the OE8’s binding posts:

- Banana Plugs (The Audiophile Standard):

- Design: Cylindrical plug with a spring-loaded, split metal pin that expands upon insertion.

- Installation: Terminate wire to plug (screw, solder, or compression). Remove plastic cap from OE8 post end. Insert plug firmly straight into the hole until seated. Hear/feel a click.

- Advantages: Extremely quick connect/disconnect; excellent conductivity; minimal contact surface corrosion; wide availability.

- Ideal For: Equipment racks, frequent system changes, high-end audio setups. OE8 Three binding post installation is effortless.

- Long-Tail Focus: “Best banana plugs for Speakercraft OE8,” “How to install banana plugs on OE8 Three.”

- Spade Connectors (Lug Connectors – Maximum Grip):

- Design: U-shaped or forked metal lug, often insulated, with a hole matching the binding post diameter.

- Installation: Terminate wire to spade lug (crimp or solder). Loosen OE8 binding post nut significantly. Slide spade fork over the exposed metal post. Ensure lug is flat against the collar base. Tighten nut firmly down onto the spade.

- Advantages: Largest contact surface area; most mechanically secure connection; excellent for high-vibration environments; robust current handling.

- Ideal For: Permanent or semi-permanent installations, outdoor speaker wiring exposed to wind/vibration, high-power applications. Crucial for OE8 speaker terminal security.

- Long-Tail Focus: “Securing OE8 speakers with spade lugs,” “Spade connector size for Speakercraft binding posts.”

- Pin Connectors (Sleek & Space-Saving):

- Design: Straight, solid metal pin, similar to a large sewing pin or nail.

- Installation: Terminate wire to pin connector. Insert pin straight into the binding post end hole (cap removed), similar to a banana plug.

- Advantages: Most compact profile; clean look; relatively secure.

- Ideal For: Tight spaces behind equipment or speakers where banana plugs might be too bulky.

- Long-Tail Focus: “Using pin connectors with in-ceiling OE8,” “Space-saving OE8 speaker connections.”

Selecting the Perfect Wire Gauge for Your OE8 Three Run

The OE8 Three’s 4-ohm impedance demands careful wire gauge selection to prevent power loss and maintain sound quality:

- The Science of Gauge & Distance: Thicker wire (lower AWG number) has less electrical resistance. Longer runs increase resistance, acting like a “bottleneck” for power, especially critical at 4 ohms.

- Speakercraft OE8 Wire Gauge Recommendations:

- Under 50 Feet: 18 AWG is the absolute minimum. 16 AWG is strongly recommended for optimal performance and headroom, even at shorter distances with 4-ohm loads.

- 50 – 100 Feet: 16 AWG is acceptable, but 14 AWG is the professional standard to minimize loss and ensure full amplifier control (damping factor).

- Over 100 Feet: 12 AWG becomes essential. The significant resistance of thinner wire over this distance would noticeably degrade bass response and overall dynamics on 4-ohm speakers.

- Why Overspecifying Can Be Wise: Using 14 AWG for runs under 50ft or 12 AWG for runs under 100ft provides significant headroom, ensures minimal signal degradation, and future-proofs your installation. Never compromise on wire quality for critical OE8 speaker wiring.

Step-by-Step: Professional Installation of Connectors to OE8

Tools You’ll Need:

- Wire strippers (correct gauge notch)

- Crimping tool (for crimp-type connectors) OR Soldering iron & solder (for solder-type)

- Small screwdriver (for set-screw connectors)

- Optional: Heat gun & adhesive-lined heat shrink tubing (for maximum strain relief/sealing, especially outdoors)

Installation Process (Universal Steps):

- Strip Precisely: Strip ~3/8″ (9-10mm) of insulation from the speaker wire end using the correct gauge notch on your strippers. Ensure clean, bright copper with no nicked strands.

- Prepare the Connector:

- Banana/Pin: Loosen the connector’s set-screw or open the clamping mechanism. Insert the bare wire fully. Tighten the screw/clamp securely. Tug firmly to test.

- Spade: Insert the bare wire fully into the spade lug barrel. Crimp using the correct die for the lug/wire gauge, applying firm pressure near the lug’s base. Inspect crimp – wires should be cold-welded, not loose. (Solder after crimping for extra assurance if desired).

- Prepare OE8 Terminal: Ensure the binding post nut is loosened enough (for spades) or the plastic end cap is removed (for bananas/pins).

- Make the Connection:

- Banana/Pin: Insert the plug firmly and straight into the post end hole until fully seated (often a click).

- Spade: Slide the spade fork fully over the exposed metal post. Ensure it sits flush. Tighten the binding post nut firmly down onto the spade lug. Do not overtighten.

- Strain Relief & Sealing (Critical for Outdoors): Slide a piece of adhesive-lined heat shrink tubing over the wire before connecting. After connection, slide the tubing over the wire/connector junction and shrink with a heat gun. This seals out moisture and prevents wire flex at the termination point. Essential for outdoor OE8 speaker longevity.

The Non-Negotiable: Polarity and Phase Integrity

- Why it Matters: Reversing positive (+) and negative (-) on just one speaker in a system causes phase cancellation. This dramatically weakens bass response, distorts soundstage imaging, and makes music sound “hollow” or unfocused.

- OE8 Connection Protocol:Always connect:

- Amplifier/Receiver + (Red) Terminal –> OE8 Speaker + (Red) Binding Post

- Amplifier/Receiver – (Black) Terminal –> OE8 Speaker – (Black) Binding Post

- Maintaining Consistency: Use wire with clear polarity markings (ridge, printing, color – often copper/+ & silver/-). Mark connectors clearly (red heat shrink, red tape, marked spades). Double-check before final tightening. A simple 1.5V battery test (touch wires to battery terminals; cone moves out when + wire touches battery +) can verify speaker polarity if unsure.

Pro Tips, Troubleshooting & Advanced Configurations

- Torque Matters: Binding post nuts should be snug but not Herculean-tight. Overtightening can strip plastic threads. Use a small torque screwdriver if possible.

- Avoiding Corrosion: For outdoor or humid environments, apply a tiny amount of dielectric grease to the metal contact surfaces (post and connector) before connection. This displaces moisture and prevents oxidation without hindering conductivity.

- Troubleshooting “No Sound” or “Intermittent Sound”:

- Check Connections First: Verify tightness at both ends (speaker and amp). A loose spade lug or banana plug is the most common culprit.

- Inspect Wire/Connectors: Look for frayed wires, broken strands at terminations, or damaged/corroded connectors.

- Verify Polarity: Ensure no reversed connections.

- Check Amp/Source: Rule out issues with the amplifier or source component.

- Multimeter Test: Use a multimeter set to continuity to check the entire speaker wire run.

- Bi-Wiring Consideration (Advanced): Some high-end installations use separate amp channels or a bi-wire-capable amp to drive the OE8’s woofer and tweeter sections independently via separate cables connected to the dedicated terminals. This requires careful amplifier configuration and understanding of impedance loads. Consult OE8 and amplifier manuals.

Conclusion: Elevate Your OE8 Experience with the Right Connection

The Speakercraft OE8 Speaker Wire Connector choice is far more than a technical detail; it’s the critical link defining your system’s reliability, longevity, and ultimate sonic potential. By understanding the OE8 Three’s versatile 5-way binding posts, selecting the optimal connector type (Banana, Spade, Pin) for your needs, meticulously following proper installation techniques—especially vital outdoor speaker sealing—and adhering strictly to correct polarity and wire gauge guidelines, you transform a simple connection into a conduit for pristine audio.

Investing in quality connectors and robust 14 AWG or 12 AWG speaker wire for runs over 50 feet ensures the OE8 Three receives the full power and control your amplifier delivers, revealing its true capabilities. Whether nestled in a living room ceiling or braving the elements outdoors, a professionally executed OE8 Three speaker connection guarantees years of immersive, high-fidelity sound. Choose wisely, install carefully, and let the music flow flawlessly.