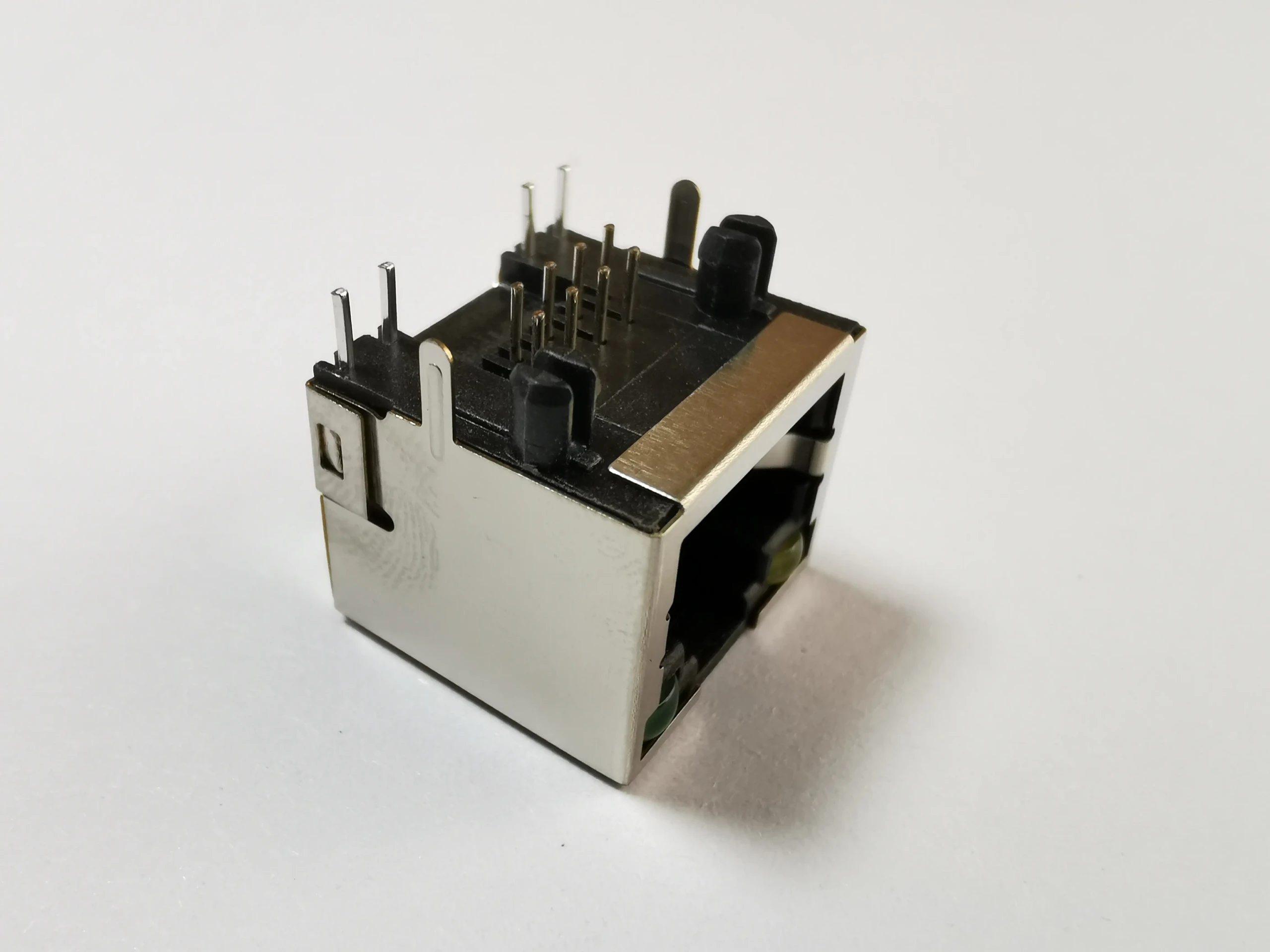

The digital age requires excellence in all connections. For those who understand real luxury, whether in high fashion footwear or smart home networks, the CAT7 RJ45 Jack represents an invisible craftsmanship for modern refined power. At our connectors Grace Spacecraft and Dragon Well Electronics for Designer Electronics, we recognize that advanced experiences require uncompromising infrastructure.

Why CAT7 defines the gold standard

Unlike mass-market alternatives, the Cat7 RJ45 jack offers connoisseur-worthy performance:

-

- 1000MHz bandwidth (2x CAT6A capacity) – Uncompressed 8K video streaming per room

-

- Personal Blocking (S/FTP) – Prevent cross-disturbance between chains like velvet-lined jewelry compartments

-

- 600MHz noise repulsion – Keep clarity even near the power cable

-

- GG45/Hybrid Compatibility – Future protection devices for emerging protocols

These specifications are important when supporting 40g data allocation, professional-grade Dolby Atmospheric Theater or microseconds to determine value high-frequency trading settings.

Manual upgrade process

The conversion of legacy devices requires surgical accuracy:

1. Outstanding Tools

-

- Fluke Networks DSX-8000 CableAnalyzer ($15,000 Professional Certified)

-

- Panduit CT-920 Crimp Tool with Titanium Mold

-

- Laser-calibrated stripper (0.1mm tolerance)

-

- 23AWG solid copper Cat7 cable (Longjing P/N: DW-C7-SP00L)

2. Termination Perfect

Step 1: Remove the Jacket

The rotating concentric leaf stripper is exactly 270° – a deeper cut than the CAT6’s 0.5mm jacket may damage the proprietary aluminum below – McGirl Shield.

Step 2: Shield Management

Unlock the woven Faraday cage (such as unboxing fashion) – Use folding technology to hold 360° with the jack’s grounding tongue at 360°.

Step 3: Pairing and Aligning

Unlike standard connectors, the CAT7 needs to remain tortuous within 3 mm of terminating. Our R&D lab measured 3.2dB near-end crosstalk degradation when it was turned only through 5mm.

Critical Insight: Dragon Well’s patent “The whole ground” Jack Design allows simultaneous termination of braided and foil screen shields – reducing installation time by 40% compared to traditional methods.

3. Verification ceremony

-

- Perform TCL/ELTCTL test (lateral conversion loss) to verify electromagnetic purity

-

- Verify impedance stability between 1-1000MHz spectrum

-

- Document insertion loss and temperature compensation (tested at 20°C ±1° tolerance)

When super high-end important

We recently equipped the St. Tropez superyacht with the standard CAT7 failed ocean certification. Our Solution:

➜Peeing the thermoplastic (rather than standard LSZH)

➜Kinick diffusion contact survived the 2000-hour salt spray test

➜Test to 15G acceleration test anti-vibration latch

result? 40Gbps backbone support submarine sonar array and holographic deck display.

There is a difference between dragons

Our customers – from Geneva watchmakers who ensure IoT workshops to Milan Design’s needs for automated textile lasers, not specifications. They need:

-

- 10 micron gold plated: The standard 3μm coating passes through after 150 insertion. Our aviation-grade processing lasts over 500 cycles.

-

- SIEMENS SIMATIS™ Implementation Tool: Automated torque calibration to terminate consistency most factories ignore

-

- Negative tolerance pin: The size of 0.002mm was processed to ensure airtight contact compression

We have 68 custom CAT7 variants (including flame retardant, oil resistant and deeper shielding models) and we solve problems that others wouldn’t expect.

Advantages of silent upgrades

For collectors, whether it’s an old-fashioned Ferrari or a digital NFT, these invisible benefits need to be considered:

-

- The integrity of the Faraday cage prevents storm signal leakage

-

- Electromagnetic radiation and CAT6A reduction by 50%

-

- Late duration consistency across 100 g flow ±0.1μsec

Legacy Integration Secret

Upgrade legacy attributes? Our team successfully hides the Cat7 infrastructure:

-

- Louis XIV Moderate Workshop

-

- Reinforced concrete listed buildings

-

- 100% humidity underground tunnel

The trick is hydrophobic gel-filled jacks and ceramic terminal blocks – the solution was born from our collaboration with our underwater robot customers.

Why compromise your canvas?

Just like custom footwear fuses with footwear made with state-of-the-art materials, your network deserves the same component of dedication. With over 300 R&D engineers specializing in high frequency connectivity and global same-day transportation from our Geneva and Singapore vaults, Dragon Well transforms invisible infrastructure into a competitive advantage.

Tomorrow’s excellence requires a perfect connection today.