Introduction

Pin header connectors are some of the most common building blocks in electronics, yet they rarely get much attention in design reviews. These simple rows of plated pins and matching female sockets quietly handle critical board-to-board and wire-to-board connections in everything from consumer gadgets and embedded modules to servers and industrial controllers.

A well-designed family of pin header connectors lets you support multiple orientations, stacking heights, pitches and currents while keeping costs under control and assembly straightforward. In this article, we’ll explore what pin header connectors are, review nine core product options you’ll find in a complete series, and share practical design tips to help you choose the right configuration for your next PCB.

What Are Pin Header Connectors?

At their simplest, pin header connectors are rectangular connectors with one or more rows of metal pins mounted to a printed circuit board (PCB). They usually mate with:

- Female header sockets on another PCB (board-to-board)

- Crimp or insulation-displacement connectors on a cable (wire-to-board)

By combining different pitches, row counts and pin lengths, manufacturers create pin header connectors that work as mezzanine stackers, edge connectors, programming interfaces, test points and more.

9 Core Types of Pin Header Connectors

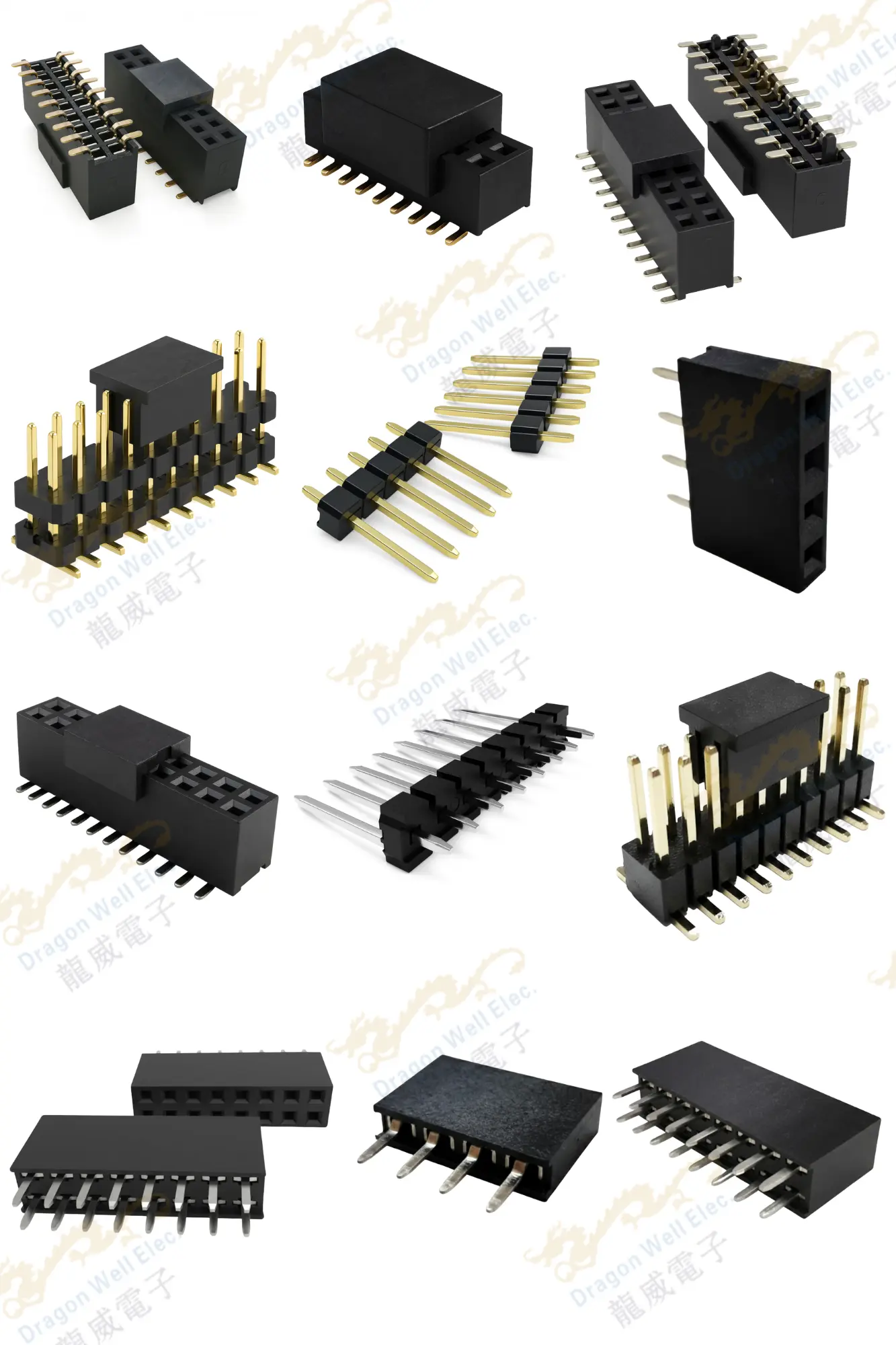

The image above shows a variety of pin header connectors and matching female headers. Let’s break them into nine core types that cover most applications.

1. Straight (Vertical) Through-Hole Headers

Vertical through-hole headers are the classic solution for connecting a daughtercard or cable perpendicular to the PCB. They provide strong solder joints and are easy to hand-assemble and rework. General-purpose 2.54 mm BergStik-style headers from brands like Amphenol are a good example of this category.

2. Right-Angle Through-Hole Headers

Right-angle headers turn the mating direction 90 degrees so connectors exit at the board edge. They are widely used for back-panel connections, low-profile enclosures and horizontal daughtercards. Many pin header connectors are offered in both straight and right-angle forms on the same pitch, simplifying PCB reuse.

3. Single-Row Female Header Sockets

Female headers mate with male pins to create simple board-to-board or board-to-cable links. Single-row versions are common as Arduino-style expansion headers, programming ports or low-pin-count signal breakouts. In a pin header connector system, these sockets share the same pitch and geometry as their matching pin strips.

4. Dual-Row and Multi-Row Female Headers

For higher signal density, dual-row and multi-row female headers pack more contacts into the same footprint. They are common on embedded processor boards, communication modules and stackable development kits. Flexible stacking solutions from suppliers like Samtec demonstrate how dense board-to-board systems can be built on pin header connectors.

5. Elevated (Stacking) Headers

Elevated or stacking headers extend pin length or raise the insulator body to create a defined spacing between two PCBs. They allow tall components or airflow between boards while maintaining reliable mating. Some series even support customized body positions for fine-tuned stacking heights.

6. Low-Profile Micro Headers

As electronics shrink, designers need smaller pin header connectors with fine pitch and low profile. Micro headers down to 1.27 mm or below can carry high-speed signals while saving board space—ideal for compact sensors, wearables and communication modules.

7. SMT Pin Header Connectors

Surface-mount (SMT) headers support full automated assembly and are essential when you want to avoid secondary wave-solder processes. SMT pin header connectors come in vertical and right-angle versions and are popular in networking, telecom and consumer electronics where volume and density are key.

8. Shrouded and Polarized Headers

Shrouded headers add plastic walls and keying around the pins to prevent mis-mating, improve strain relief and guide the mating connector. When paired with locking cable housings, they form robust wire-to-board systems used in power electronics, industrial control and automotive assemblies.

9. Custom and Breakaway Header Strips

Finally, many projects rely on breakaway strips that can be snapped to custom lengths or on semi-custom headers with special pin lengths, locks or plating. Vendors like Molex offer configurable custom headers to eliminate manual pin-stitching and align perfectly with your PCB layout.

Key Design Considerations for Pin Header Connectors

When choosing pin header connectors for a new design, look beyond pin count and price. Several technical details have a big impact on long-term performance.

Pitch and Density

Common pitches include 2.54 mm, 2.00 mm, 1.27 mm and smaller. Wider pitch is easier to route and assemble; finer pitch increases density but demands tighter tolerances and better process control. Select a pitch that balances space, manufacturability and your expected data rates.

Contact Plating and Current Rating

The contact plating and cross-section determine both signal integrity and power capability. Gold plating improves corrosion resistance and is ideal for low-level signals and frequent mating; tin plating is cost-effective for many power and general-purpose connections. Always verify maximum current ratings per pin and consider temperature rise for stacked connectors.

Mechanical Retention and Alignment

Features like board locks, friction ribs and polarization keys keep pin header connectors firmly seated during soldering and use. For stacking systems, precise alignment between header and socket prevents bent pins and improves reliability under shock and vibration.

Assembly Process

If your PCB is mostly SMT and reflowed in a single pass, SMT pin header connectors or pin-in-paste solutions may reduce process steps. For mixed or low-volume builds, through-hole parts are still attractive thanks to their robustness and easy manual handling.

Typical Applications for Pin Header Connectors

Because they are modular and affordable, pin header connectors are used in nearly every market:

- Embedded control boards and development kits

- Industrial automation, PLCs and I/O cards

- Telecom and networking equipment

- Consumer and IoT devices

- Power supplies and battery systems

- Medical and test instruments

Board-to-board connector families from Amphenol, Molex and Samtec commonly combine pin header connectors with mezzanine, backplane and coplanar solutions to build complete signal and power architectures.

Best Practices for Using Pin Header Connectors in Your PCB Design

To get the best performance from your chosen pin header connectors, keep these practical tips in mind:

- Follow the recommended land patterns and drill sizes from the connector datasheet to ensure good solder fillets and reliable joints.

- Maintain clearance and creepage between adjacent rows and neighboring circuitry, especially when carrying higher voltages or mixed-signal lines.

- Consider test access: leave enough space for probes and rework tools around headers that may need troubleshooting.

- Add mechanical support for heavy daughterboards or cables using standoffs or brackets so the connector is not carrying all the mechanical load.

- Standardize where possible: using the same pitch and family of pin header connectors across multiple projects simplifies your BOM and speeds up new designs.

Why Partner with Dragon Well for Pin Header Connectors

Global leaders such as Amphenol, Molex and Samtec showcase what’s possible with advanced board-to-board and stacking systems.

Dragon Well Electronics focuses on delivering pin header connectors and matching female sockets that pair this level of engineering with cost-effective manufacturing. Our portfolio includes:

- Vertical and right-angle pin header connectors in multiple pitches

- Elevated and low-profile stacking headers

- Gold-plated and tin-plated options for different environments

- Custom lengths and special pin configurations for OEM/ODM projects

We can match plating, pin length, and packing codes one-to-one with your existing designs, providing an easy path to cost-down cross-references without changing your PCB.

Order & RFQ

Need samples or a cost-down cross-reference for your pin header connectors project? Share your BOM or drawing and we’ll match plating and packing codes 1:1.

- Websites: cndragonwell.com || dw-tek.com

- Email: prothick@cndragonwell.com

Connect with Us

Stay up to date with new pin header connectors, stacking headers and board-to-board solutions: