The Shielded RJ45 Connectors – the familiar plastic clips found on nearly all Ethernet cables – belies increasingly important engineering decisions. In an era where data requirements are exponentially upgraded, electromagnetic interference (EMI) proliferated from countless wireless devices, so understanding the difference between standard and shielded RJ45 connectors is crucial for those who take performance seriously.

Silent Breaker: Why Blocking is Important in Modern Networks

Imagine having a party where the whispers of conversation are statically submerged. This is exactly when the EMI of the motor, fluorescent lamp, wireless transmitter and even adjacent cables, which happens in an unshielded network environment. “noise.” This interference is manifested as:

-

- Corrupted packets Need to be redisseminated

-

- Incubation period peak Cracking real-time applications (4K streaming, VoIP, industrial automation)

-

- Maximum distance limit More than 100 meters

-

- Security vulnerabilities Through interceptable EMI emissions

The standard RJ45 connector (using UTP – unshielded twisted pair of cables) relies solely on wire twist to remove interference. Although sufficient for basic home networks, it proves that this is insufficient in an environment where signal integrity is not negotiable.

Decoding masking RJ45: Accurate engineering for harsh environments

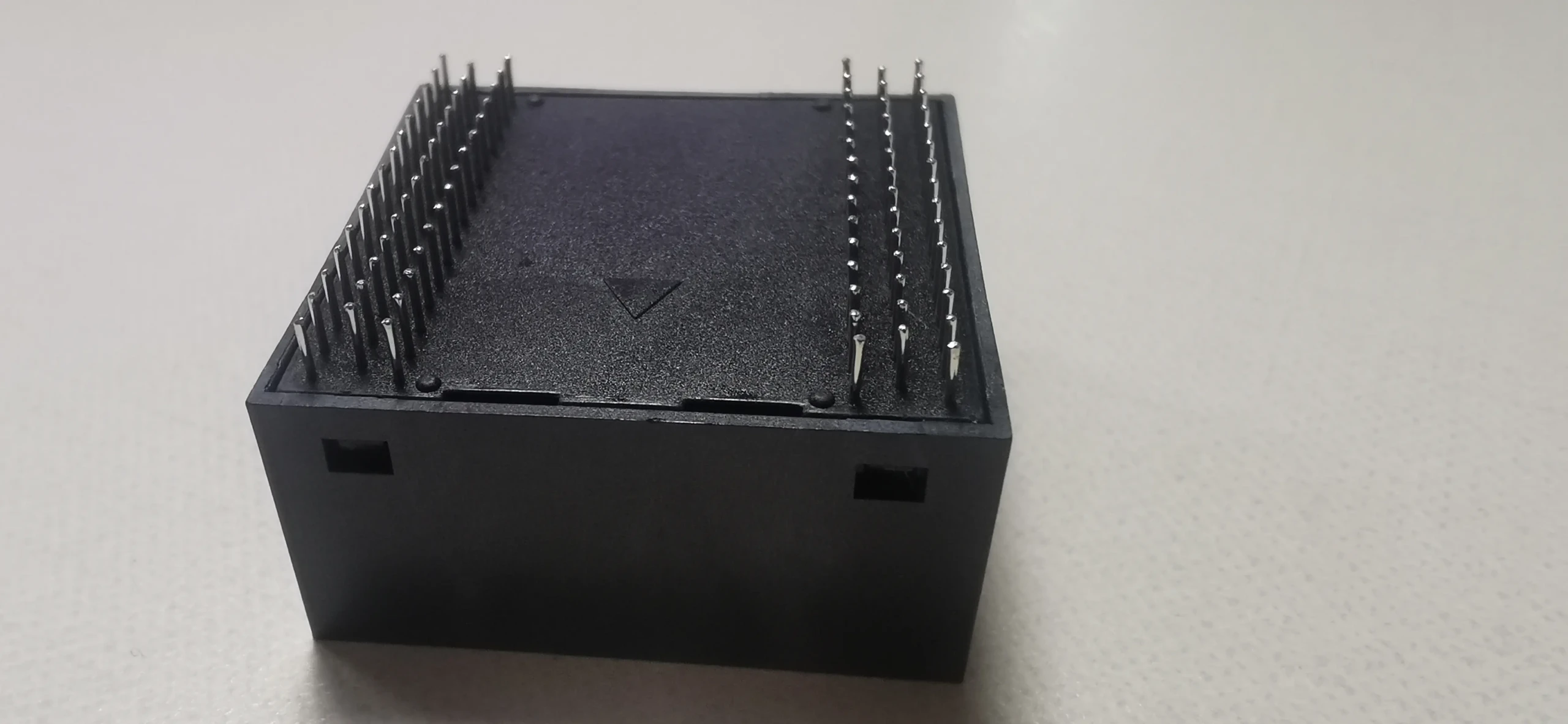

The shielded RJ45 connector integrates multiple protection layers:

-

- Personal-to-blocking (PIMF)

Each twisted pair receives a metal foil wrap to prevent crosstalk between the pairs.

- Personal-to-blocking (PIMF)

-

- Overall foil screen shielding (F/UTP or S/FTP)

The foil or braided screen covers all pairs under the cable jacket.

- Overall foil screen shielding (F/UTP or S/FTP)

-

- Conductive connector housing

Metalized plastic or all-metal shells generate 360° EMI control by continuity with shielded cables.

- Conductive connector housing

-

- Ground contact

An integrated metal spring or clip establishes a path directly to the ground, transferring interference to the signal.

- Ground contact

The shielded RJ45 becomes an essential place

-

- Industrial automation: Factory floors with frequency drives, servo motors and welding equipment produce extreme EMI. Shielded connectors are insurance against catastrophic communication failures.

-

- High density installation: Thousands of cables stacked in data centers introduce alien crosstalk – interference between adjacent cables. Mask contains signal overflow.

-

- Transport/Marine Corps: Engine compartments, avionics bays and radar systems require exemptions to the strong EMI field.

-

- Medical Imaging: MRI kits and sensitive diagnostic devices cannot tolerate signal degradation.

-

- 5G infrastructure: Millimeter wave deployment increases sensitivity to nearby hardware interference.

Subtle balance: Not every device needs to be shielded

Ironically, improper use of shielded RJ45 connectors can Downgrade Performance. Main things to note:

-

- Complete grounding continuity: Shields can only work if it is properly grounded through compatible patch panels, switches and cables. Incomplete ground rings create antennas, thereby amplifying interference.

-

- Installation expertise: Bending radius, termination technique (avoiding shield wear) and humidity exposure affect performance.

-

- Cost and Benefit Analysis: The cost of shielding systems is 30-50% higher than that of UTP. For short-term operation in a home office, UTP is usually sufficient.

Dragon Well’s engineering edges are in shielded connectivity

Since 2007, we have perfected the shielded RJ45 design to meet invisible challenges:

-

- Mixed shielding materials: Combining the stainless steel shell with gold-plated contact can balance durability with optimal conductivity even in sulfur environments such as oil drills and even in sulfur-rich environments.

-

- No tool termination: The patented IDC (Insulated Displacement Contact) design allows for anti-mis-shielding grounding without specialized tools.

-

- Vibration resistance: The Automotive-grade Lock Tab (tested to 100g impact load) ensures the connection remains in a high vibration industrial environment – many consumer-grade shielded connectors are defective.

-

- Custom dielectric insulators: The proprietary polymers are mixed together to minimize signal loss at most gabit frequencies, and the CAT 8.2 standard (2000MHz, 40Gbps) was tested.

Example: Our S-RJ45-10GX series was deployed in Tokyo Automation Port, maintaining 24/7 operation in wireless networks sold by cranes and megawatt charging stations, achieving zero packaging losses in 48 months.

The future of shielding prevention: Beyond Gigabit Ethernet

As the network develops towards 25G/40G on copper (802.3BQ) and POE++ (90W), the bet for noise immunity has escalated. Shielded RJ45 connector is enabled:

-

- Extended power to Ethernet (POE) runs: Shielding reduces voltage droplets and heat accumulation in high welding applications such as PTZ cameras and LED arrays.

-

- Single-type AVB (audio and video bridge): Uncompressed 4K video transport in broadcast studios is crucial.

-

- IIOT sensor network: Reliable microsecond synchronization in industrial IoT networks.

Customized analogy: Why precision is crucial

Like the master tailor, the suit is reinforced with hidden stretching, shielded RJ45 connectors, leaving the critical data pathway unnoticed. A shelved solution may sew seams when stressed; engineers endure.

At Dragon Well, we approach each connector with the precision of high-end fashion – 402 R&D experts iterate shield geometry in EM simulation software, verify prototypes in Anechoic Chambers, and audit supply chains to ensure metallurgical consistency. This obsession ensures that whether you deploy a fine smart home system or secure a satellite ground station, your physical layer goes beyond the commodity state and becomes a competitive asset.

Strategic Choice

The choice of shielded RJ45 connector goes beyond electrical specifications – this is a risk mitigation strategy for tasks, where data integrity is directly related to revenue, security, or reputation. Working with engineers, they deal with the de-micro-interaction and macro-EMI landscapes in contact interfaces are essential.

This is not only a connectivity designed to work, but also an improvement.