In a world of increasingly connected technologies intersect with all aspects of luxury life – from marine audio systems on yachts to climate-controlled shoe repositories – unceremonious waterproof connectors become the key facilitator of seamless innovation. For creators of unacceptable advanced equipment, choosing the right waterproof interface is more than engineering; it is material planning that defines the legacy of the product.

Silent Guardian of Luxury Show

Consider your €3,000 diving watch that survives the pressure of 300 meters or the discreet outdoor speakers in the infinity pool of Beverly Hills that deliver crystal sounds through the monsoon. These experiences are flawless on the connector in the event of normal components failure. The global waterproof connector market is expected to reach USD 17.2 billion by 2029, reflecting the essential role these components play in high-value applications.

IP Rating: Decoded Liquid Armor

The cornerstone of waterproof selection begins with understanding surface-level definitions outside of IP (Inlet Protection) code:

-

Semantic nuances between IPX6 and IPX7

Devices that survive the directional sea jet (IPX6) may succumb to the champagne barrel (IPX7). Luxury marine equipment usually requires dual-stage IPX6/7 compliance. -

The pressure paradox

IPX8 rating specifies protection over 1 meter, but depth tolerances vary between manufacturers. Despite sharing the same IP classification, the rated 3-meter flooded connector does not protect the 50-meter submarine camera housing. - Crack Corrosion War

ASTM B117 Salt Spray Test Reveals What General IP Ratings Is Obscure – How 316-liter marine grade stainless steel contacts resist chloride attacks, thereby reducing standard alloys in coastal environments.

Material Alchemy for Identification of Applications

Command: Hidden Hierarchy

-

Palladium Nickel Alloy

In keeping low loop applications (10,000+ loops), surpassing gold while maintaining contact resistance below 10MΩ – ideal for modular smart closets with automatic clothing search systems. - Thermoplastics injected with PTFE

Compared to the standard PBT housing, the self-lubricating characteristics reduce mating force by 40%, thus retaining the integrity of the audio diamond cutting finish.

Hybrid housing architecture

Innovators now merge material science:

- Carbon fiber reinforced liquid crystal polymer

Achieving tensile strength of 240MPA with water absorption of 0.02% – Paradigm transfer of aviation headphones requires a lightweight seal.

Meeting technical poems in environment je

Redefinition of extreme temperatures

Traditional connectors falter on the border, while engineering solutions thrive:

- Silicone-free sealing system: Operate cleanly from -65°C (Arctic Expedition Gear) to +200°C (Module inside the car) without deviating from contaminants to sensitive components.

Vibration problem

High-speed vessel instrumentation requires connectors to reduce the impact of G-Force:

- Three lock system: Combined threaded coupling, bayonet lock and spring-type interface maintain signal integrity through 35G vibrating load.

Electromagnetic sacredness of luxury technology

Where the brushed aluminum case complies with 5G connectivity, protection goes beyond physical seals:

- Directional shield weaving technology

360° EMI/RFI protection reaches 120DB attenuation, up to 40GHz – critical to performing confidential communications of the vehicle.

Compatibility: Integrated ballet

Luxury technology paradox

Smooth industrial design often clashes with strong sealing requirements. Advanced solutions via:

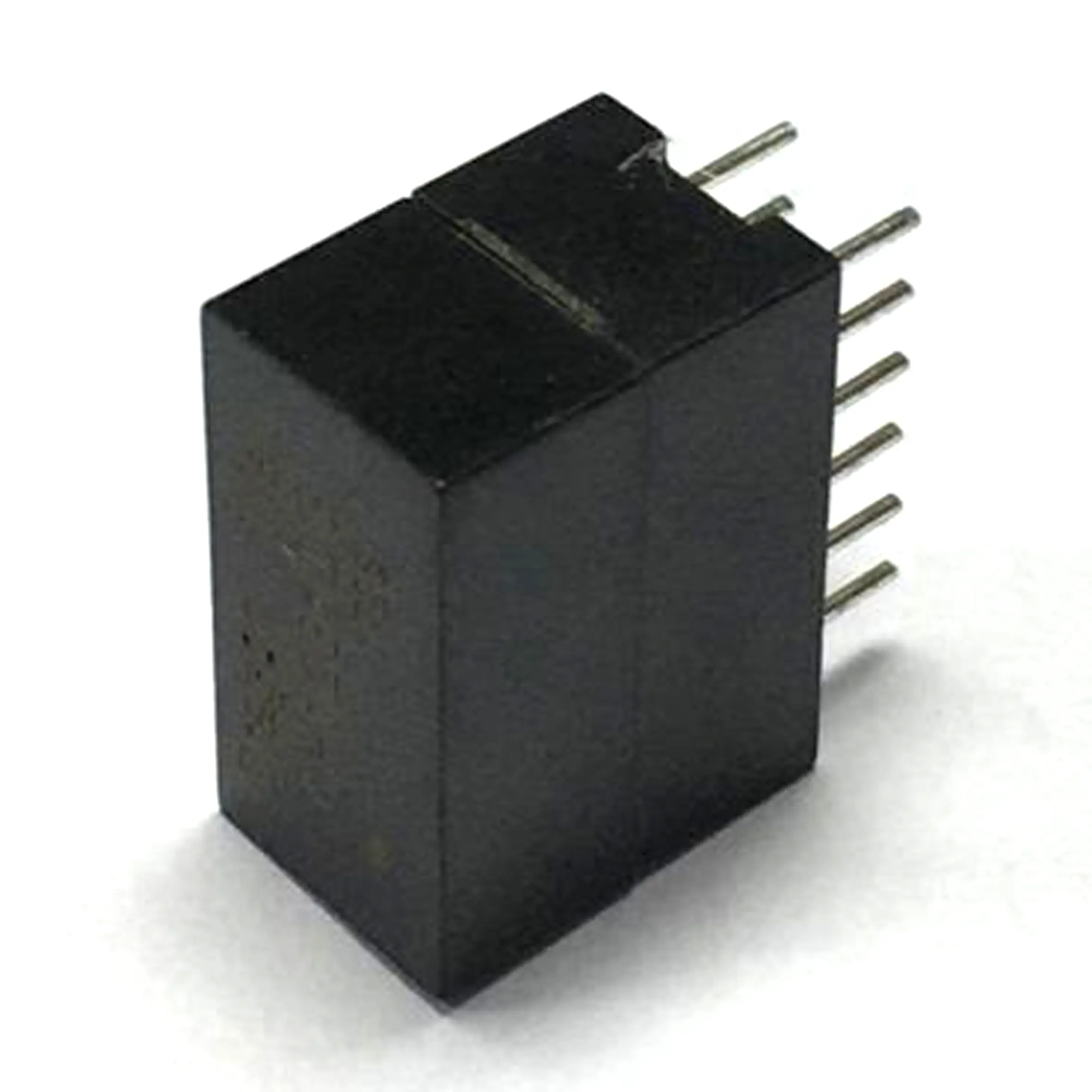

- Micro-IP67 nano rectangular connector: 15 contact configurations in the 6mm configuration file maintain IP67 protection while disappearing into the designer smart mirror.

Hybrid power + data channel

High combat applications require comprehensive thinking:

- 12-in-1 hybrid interface: Simultaneously process 100W USB-PD, 10GBPS optical data and pneumatic controls in a single IP69K-class housing for robotic baler systems.

Chronicles of Extreme Applications

Superyacht Command Center

Multi-sensor marine networks deploy connectors with the following methods:

- Titanium catheter resists barnacle acid

- Dynamic pressure compensation system

- Hydrophobic nanocoatings prevent micro-droplets

Advanced Advanced Technology Integration

Customized wearable designer designation:

- Magnetic fluid connectors enable seamless jewelry conversion

- 24k gold-plated contacts that maintain conductivity through perfume and skin oil

Installation: Final Covenant

Even the Prime Connector, there is no proper debugging failure:

- Torque sequence scheme: 80% of premature failures are caused by uneven gland compression.

- Cable boot geometry diagram Match the sheath diameter within 0.25 mm tolerance to prevent capillary water from traveling.

- Dielectric regulation: Custom made grease matching fluid dielectric constant to prevent signal leakage in submerged MEMS sensors.

Global support architecture for elite creators

Leading manufacturers now offer concierge engineering services, including:

- Application-specific test drill: Simulate Himalayan altitude pressure or Dubai sand wind vaccine

- 3D Sealing Curve Optimization: Nonlinear FEA modeling of irregular mating surfaces

- On-site fault evidence collection: Return to the micro CT scan of the connector to identify the nanoscale inlet path

The horizon of innovative hydrophobic

Emerging technologies redefined possibilities:

- Self-healing elastomer: Micro-encapsulated healing agent autonomously sealed 0.3mm puncture defect

- Quantum tunnel connector: Electronic grade sealing makes submersible operations on molecular gaps traditionally impossible to waterproof

- Biologically inspired design: Shark tooth-like texture reduces fluid dynamic resistance while repelling microbial growth

At the confluence of advanced technology and uncompromising performance, the waterproof connector choice goes beyond technology procurement. It becomes an exercise in maintaining technical integrity beneath an elegant surface – ensuring that continuity remains absolute in Monte Carlo ocean depth or in alpine electronic art installations. Enlightened creators recognize that in luxury electronics, hidden parts quality defines the experience they provide.