Mastering Accuracy: The Art of RJ45 Male Connector Installation

In an age where seamless connectivity defines complexity, the ability to make perfect Ethernet connections goes beyond practicality – it becomes the act of precise engineering worthy of luxury craftsmanship. Whether it’s upgrading a custom home theater, equipped with a designer smart home, or ensuring perfect data transfer for high-end audio systems, understanding RJ45 male connector installation is a key skill in identifying technical trajectories. This guide reveals the rigorous technology favored by industry professionals, turning the original cable into a perfect connection worthy of the most demanding environments.

I. Basic Toolkit: Curatorial Excellence

Just as a watchman chooses a specific tool for complex mechanisms, appropriate RJ45 termination requires precise instrumentation:

-

- CAT6/CAT6A Ethernet cable: Select a certified manufacturer’s shielded, pure copper conductor (24AWG) – ideal for 10Gbps performance in a fever-grade network

-

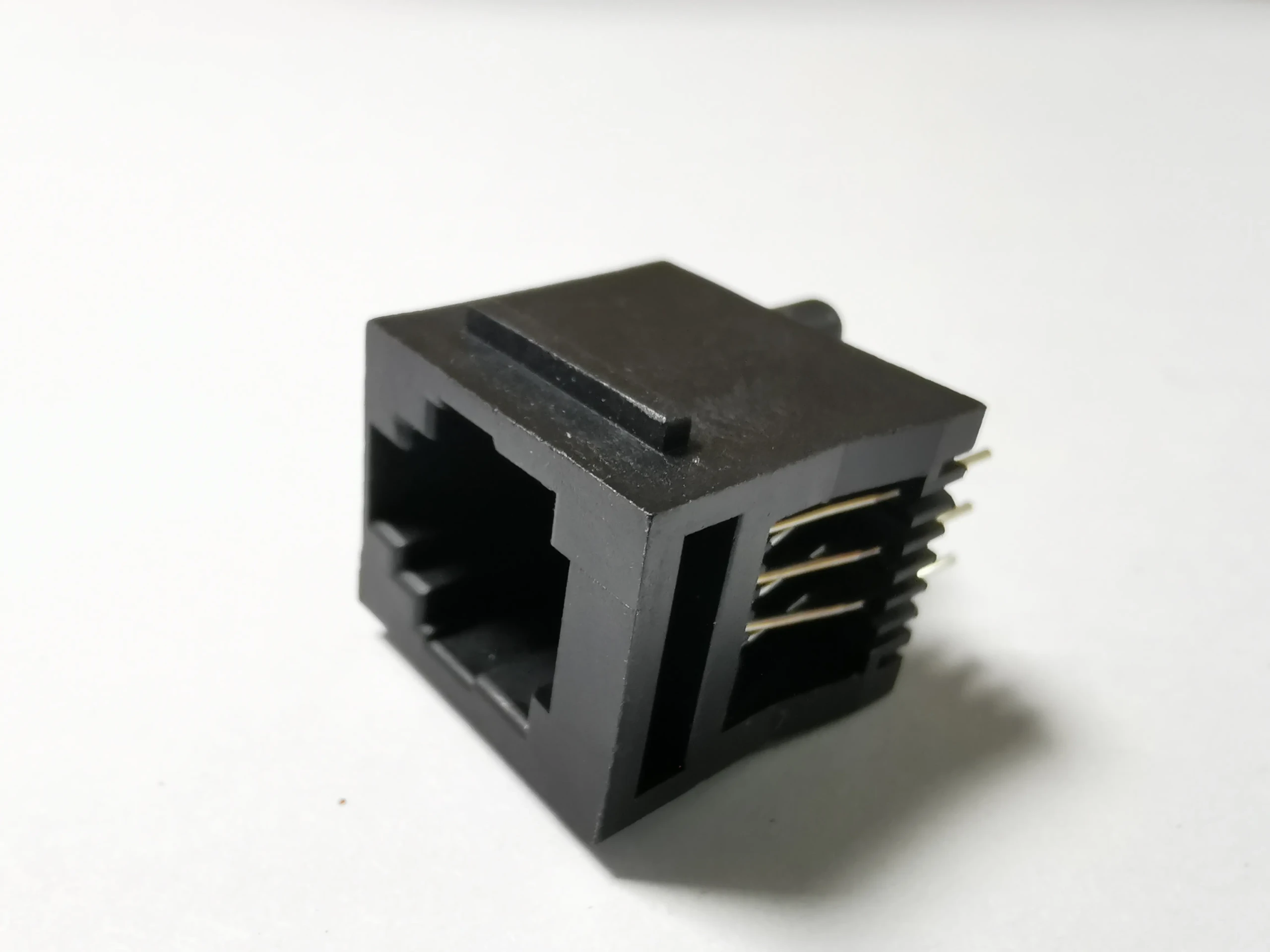

- RJ45 Modular Connector: Gold-plated 8p8c connector with strain boots, preferably with load bars for wire alignment

-

- Wire stripper with depth gauge: Prevent damage to the conductor insulation material (strips exactly 1.5″ coat)

-

- Rinse and cut: For perfect tailoring without deformation

-

- Modular crimping tool: Invest in ratchet models with interchangeable molds (CAT5E/6/6A specific)

-

- LAN Testing: Professional grade unit with TDR diagnosis (e.g., Fluke Linkiq)

-

- Punching tool (optional): Keystone Jack preparation for permanent installation

ii. Color code puzzle: T568A and T568B

Just like decoding the Savile Row suit mode, wiring standards require strict compliance:

-

- T568B 95% of the dominant commercial facilities (main host in the United States/Asia)

-

- T568A Cross green/orange pair (needed in government/traditional EU system)

-

- Key Rules:exist Both ends– Mixing causes polarity reversal

| Pin Position | T568A | T568B |

|---|---|---|

| 1 | White/green | White/orange |

| 2 | Green | orange |

| 3 | White/orange | White/green |

| 4 | Blue | Blue |

| 5 | White/Blue | White/Blue |

| 6 | orange | Green |

| 7 | White/brown | White/brown |

| 8 | Brown | Brown |

Pro Insight: For 10GBASE-T applications, please keep the twists and turns within 1/4″ Terminate to prevent alien crosstalk.

iii. Termination ceremony: 9 precise steps

1. Jacket peeling

Use a calibrated stripper to remove 1.5 accurately” Coat – Floor-standing tool 180° to avoid scoring conductors. Cut nylon tear rope for clean aesthetics.

2. Pairing preparation

When arranged in T568B order, the wist pairs are the least:

-

- White/orange→orange→white/green→blue→white/blue→green→white/brown→brown

3. Flat and aligned

Roll the wires between the thumb/index fingers for flat alignment. Decoration ends at 1/2 angle at 90°” length.

Professional Secret: Temporarily freeze the fabric with aerosol contact cleaner to stabilize wire positioning.

4. Load bar insertion (if applicable)

Slide the wires through the integrated load bar channel of the connector until the insulation reaches the rear station.

5. Connector participation

Insert the wire into RJ45 until the conductor bottoms at the front window. Verify the color sequence with transparent plastic.

6. Start the integration

Slide the strain release shoe into the cable before crimping – which can lead to expensive rework.

7. Crimp Alchemy

Place the connector into the tool’s RJ45 mold. Apply a firm pressure until the ratchet is released – signal contact Pierce insulation and grip conductor.

8. Visual inspection

examine:

-

- Brass contact total depression and rinsing

-

- Jacket received by strain relief pressure

-

- No copper can be seen behind the contact

9. Verification test

Use a LAN tester to confirm:

-

- Continuity of all 8 conductors

-

- Correct pin mapping

-

- No split pairs (e.g., pin 3 and 6 are incorrect)

-

- Resistance <25Ω per pair

iv. Custom Troubleshooting: Curated Perfect

symptom → diagnosis → remedy

-

- Intermittent 1GBPS speed →Split pairs → Redefine using Pair Keeper

-

- Connection drops at 55°C →Cut copper aluminum → Use pure copper Cat6a instead

-

- Slope voltage drop →Insufficient contact depth → Additional power

-

- EMI in VR installation →Unshielded connector →Installing ferrite core +Shielded RJ45

Designer Tips: For inner wall runs, use 110 block tools to terminate in the Keystone jack and then use prefabricated patch cables – start cable integrity while accommodating future reconfigurations.

V. Longjing Bad: Connectivity as Art

At Dragon Well Electronics, we approach each connector with the accuracy of Swiss watches. Our MIL-SPEC RJ45 connector features:

-

- 50m” Nickel-plated gold: No degradation of the insertion cycle above 10,000

-

- Anti-stimulation boot design: Enhanced TPU, release 180°

-

- HVAC rating insulation: Stable from -40°C to 105°C

-

- EMI/RFI shielding: Three layers of foil + braid

Final Thought

In elite networks, whether it’s streaming 32-bit/768kHz audio or smart mirrors synchronized in a penthouse suite – the RJ45 termination remains an unbreeding masterpiece. By executing these techniques with a jeweler’s focus, you can transform utilitarian connections into a lasting feat of microengineering.

Discover connoisseur-grade connectivity solutions on Dragon Well Electronics, each PIN contact reflects eighteen years of obsession.